FRP Process Monitoring sensor for electrical Conductive & Non-conductive composite

Non-contacting (invasive) FRP (Fibre-Reinforced Plastic) process monitor sensor.

The ideal sensor that can be used for almost every process and material that is under change during the production. Because during the process change, from a mostly liquid into a solid material, the electrical behaviour of the ratio between magnetic and capacitive field signal components is changing too.

During process changes the material is subject to an electric field, the negatively charged electrons and positively charged atomic nuclei are subject to opposite forces and undergo charge separation. This polarizability is responsible for a material's dielectric constant. And it is this behavior change that can be measured with the sensor.

There is no need to have physical contact with the material in order to measure the process behaviour. The sensor can be put on top of the vacuum bag or integrated in the mold shell surface.

The sensor that can be used for production process monitoring of all FRP´s composite materials with:

Non-conductive fibres

- Glass

- Aramid

- Bio-based, etc.

Conductive fibres

- Carbon

- Hybrid wire-mesh and EME shielding, etc.

There is no need to have physical contact with the material in order to measure the process behaviour. The sensor can be put on top of the vacuum bag or integrated in the mold shell surface.

- The reusable sensor is measuring process changes and suitable for:

- Vacuum Infusion Molding / VARTM

- Vacuum infusion / RTM

- Prepreg Curing

- Thermoplastic Welding

- Process control

- Flow and Curing simulation

- Vacuum Infusion Molding / VARTM

It can be used in all types of composite fibre reinforcement. Major advantages of the Twenco contactless sensor technology are:

- No leakage risk compared to embedded sensors, less intrusive.

- Less labour.

- More flexible, the sensor can be placed on various locations, whereas the embedded sensors are usually outside the net-contour.

- No influence of the sensor and attached wires on the resin flow behaviour.

With the contactless Twenco sensor the complete process can be monitored at the sensor location from start to finish, detecting resin arrival, flow speed, viscosity behaviour and resin cure. The sensor is noninvasive and can be placed on top of the vacuum bag.

- RTM

Same process monitoring as with VARTM, however the sensor is embedded in the mold shell.

In a metal mold at the surface covered with a Teflon layer (or equal material).

In a composite mold imbedded under the surface covered with a glass fibre layer. Electrical heating (50/60Hz VAC embedded tracing wires) have no negative effects on the sensor signal.

- Prepreg curing

Process monitoring start directly at the moment of curing and will detect the viscosity behaviour up till final curing end stage.

- Thermoplastic Welding

During resistance or conduction welding, the melting process can be monitored inside the 2 layers material. The sensor can be integrated in the weld pressing construction.

With a data interface between the sensor and the welding power device, the welding viscosity change can be measured and welding power can real-time controlled.

- Using process monitoring in combination with mould heating, you get the benefit of a complete real time controlled production process. Knowing what happens inside the mould and controlling the temperature accordingly.

- Process simulation

Depending on the capabilities of your process simulation software. It is possible to use real-time measured process data as input for flow and curing simulation. The simulation software can recalculate the process behaviour and predict real-time what’s happens next. Also afterwards with the Twenco Analyse Software the process timestamps can be easy detected. And reported data can be used for optimization of the simulation model.

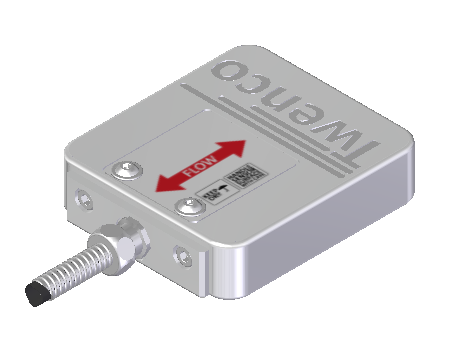

Process Monitor Sensor

FRP Process Monitor Sensor

Sensor Side view

FRP Process Monitor Sensor

Process Monitor Sensor

FRP Process Monitor Sensor